Ocean Technical & Mechanical Services takes pride in stating that we source, assess, and deliver the best-in-class products to our customers for myriad industrial purposes. When it comes to acoustic cameras, we work with SONASCREEN from the ultrasonic equipment leader, SONOTEC.

This state-of-the-art acoustic camera generates acoustic images from the ultrasound as well as audible frequency ranges in real time, allowing maintenance personnel to detect leaks in compressed air and vacuum systems swiftly. Additionally, the camera also provides audible feedback which can be heard via industrial headphones, making the ultrasound both visible and audible. It is an efficient device for energy audit and predictive maintenance, and helps ensure both energy efficiency as well as operational dependability.

More Accurate And Efficient Maintenance Workflows

SONASCREEN localizes the sources of the sound, and visualizes sophisticated acoustic information in multiple colors (as an acoustic photo and video), extending your visibility to areas which you can’t see with your eyes. The location of the sound sources in wave fields like ultrasound fields is ascertained through a method called beamforming.

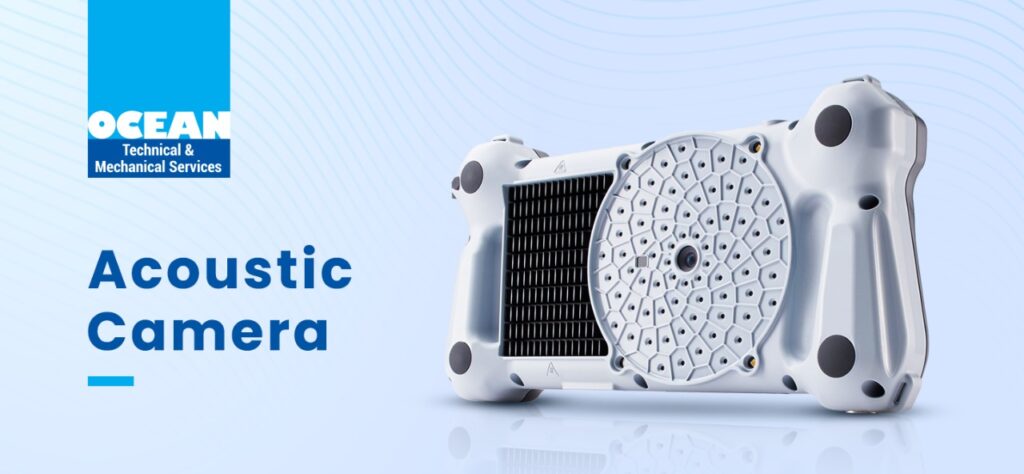

The device is easy to handle, and has pre-set profiles to detect leaks, so even newbies can use the device as well as interpret the results correctly with just a glance. It is optimal for industrial use as it has an exceptionally sensitive suite of 72 mikes and IP54 protection. The spiral array elicits much superior results and excellent acoustic dynamic range when compared to other designs. The camera can be used for a wide range of applications for detecting sound waves and sources in both the ultrasonic and audible ranges. The captured acoustic images are displayed in real time, in a hi-res screen with an exceptional frame rate of 100 fps. The global shutter incorporated in the devices helps to eliminate effects of the rolling shutter, allowing the perfect capture of rapidly moving objects by the user.

The adjustable bandpass filter allows the user to focus on different frequency ranges and bandwidths based on the application and the emitted acoustic signals. Depending on what frequency the user is focusing on, he can detect sound sources up to 150 m away. Furthermore, the camera’s dynamic range can be adjusted to mask out sources of interference, even in noisy industrial environments. In addition, the device provides acoustic feedback via industrial headphones. This allows maintenance personnel to listen to the measurements in addition to the visual evaluation.

PC Software & Reporting

Recorded images and videos are stored directly on the device and can be exported for reporting to a PC/laptop. The software provides parameters for subsequent processing and analysis of the measurement results. For long distance measurements or location-independent measurement, the camera can be controlled by the PC software via an ethernet connection.

One Camera for multiple applications

- Detection of compressed air and vacuum system leaks

Leaks in compressed air and vacuum systems cause significant costs. Therefore, the fast repair of compressed leaks saves time and money, while also reducing CO2 emissions. By introducing the new acoustic camera SONASCREEN, SONOTEC provides another tool to its customers to meet their energy efficiency targets.

With the help of the acoustic imager, large areas can be scanned for leaks quickly, saving time and money. Acoustic imaging has never been so easy: the pre-set leak detection profile provides a simple entry to leak detection with an acoustic camera. Multiple leaks can be pinpointed and displayed at the same time easily. The intuitive reporting is supplemented by a tool for leakage cost calculation.

- Electrical asset reliability

At high-voltage transmission lines and in substations, noticeable ultrasound signals are not uncommon and are often indicators for defects. The acoustical visualization of ultrasound allows defective components to be identified with pinpoint accuracy and without interrupting plant operation.

By using the SONASCREEN, maintenance staff can easily detect high-frequency sounds from partial discharge, such as corona, tracking or arcing. Furthermore, typical forms of partial discharge can be recognized in the spectrogram. Regular ultrasonic inspections of electrical assets will help to detect partial discharges at the earliest stage and to ensure plant reliability and safety.

Features at a glance:

• 72 sealed microphones (spiral array) for use in industrial areas

• Real-time acoustic results at 100 fps for real time results

• Wide frequency range: 10 Hz to 100 kHz for the detection of audible sound and ultrasound

• Integrated data acquisition and analysis software

• Handheld device with IP54 protection (splash proof)

• Integrated LED lights

• 8 configurable buttons for fast control

• Low weight and small size