Wireless Condition Monitoring

Wireless condition monitoring helps to keep track of the machine’s health continuously and get the most efficiency from their assets, thus maximising asset availability, minimising downtime and reducing costs. This system is extremely important to the industries since asset failures will lead to loss of production and we can also reduce the man-hours spent on preventive maintenance.

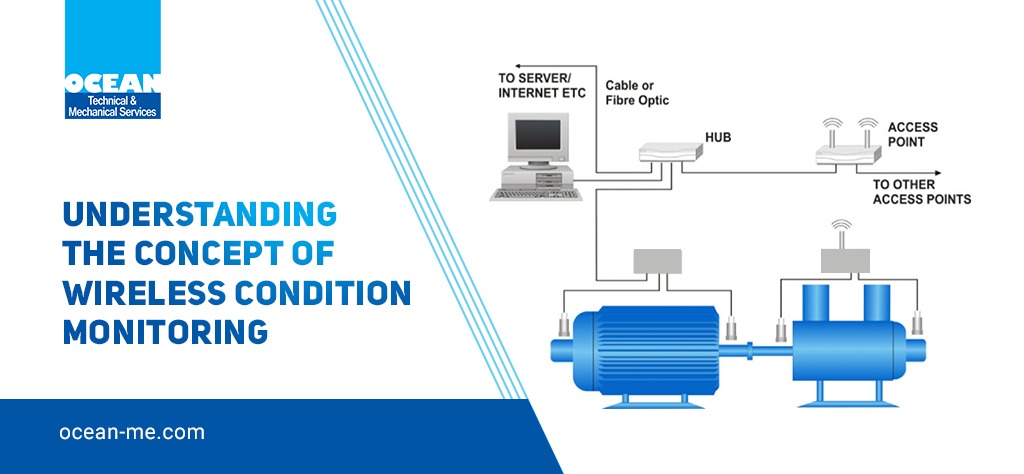

Wireless sensors allow the reliability maintenance team to monitor more channels with fewer resources. It detects machine vibrations and temperature abnormalities that could lead to equipment failure and production downtime. Information provided by the system can be accessed remotely by users. Daily measurements of machines in risky, isolated, and difficult-to-reach places are possible with the wireless condition monitoring system.

Read more about:

- Guidelines For Condition Based Maintenance

- Vibration Sensors: Functions and Applications

- Ultrasonic Steam Trap Testing

Benefits of Wireless Condition Monitoring

- It can be easily installed on existing assets without requiring any additional modifications.

- Cost-effective when compared to traditional wired solutions.-Reduces cost of offline monitoring and planned maintenance

- Data provided by the system can be accessed remotely by end users.

- Wireless monitoring detects any changes or variations that are different from their normal operations to give enough time to take appropriate actions. It’s a terrific approach to cut costs associated with unplanned and undesirable downtime, which has an influence on a company’s profit margins.

- Wireless monitoring helps to extend the life of equipment . It’s not only cost-effective, but it’s also a technique to get the most out of the equipment and plant. According to research, if the flaws that were spotted by wireless condition monitoring systems are repaired at the earliest, it can save up to 40% of operational expenditures.

- ability to increase or decrease in performance , in response to changes in application and system processing demands

- The most important advantage of wireless monitoring is that it can follow constantly changing parameters of machinery health and attempt to provide alerts about any defects or malfunctions. With advance notice, the required precautions can be taken to prevent future damage. Moreover, wireless monitoring allows for the collection of real-time data via numerous sensors, which can keep people informed about the asset’s general health. It’s an attempt to provide a full explanation of the machine’s dos and don’ts so that operational managers don’t have to wait for any defective indicators to trigger alarms.

- Wireless monitoring is a component of artificial intelligence and machine learning, as well as the Internet of Things (IoT) in condition monitoring. Enables businesses to gain the benefits of moving from reactive to preventive maintenance.

Conclusion

The time it takes for operators to monitor the assets’ correct operation has been drastically decreased ,thanks to wireless condition monitoring. Today’s world is one-of-a-kind and fast-paced. It’s all about “this moment.” It’s all possible with wireless condition monitoring. Wireless condition monitoring ensures high productivity and efficient production in all manufacturing units. It also embraces real-time and cost-effective technologies. If you are looking for the best wireless condition monitoring services in Oman, Ocean Technical and Mechanical Services LLC is the perfect place for you.