Every crane system operation can differ in terms of its specifications. It is because the needs of each project are different from the others and have different threshold values to determine the endurance and performance of the corresponding project. The most vital part of elevating a crane apparatus is an electrification system.

The key components provide the necessary one-phase or three-phase energy supply to function the crane operations like contactors and limit switches. There are three primary parts in a crane electrification system: conductors, festoon cables, and cable reels.

Here, let’s see how a festoon cable system works and its benefits as a crane system. We will also explain how many types of festoon cable systems are available in the industry.

What Is a Festoon Cable System?

The festoon cable system in an electrification apparatus acts as a bridge between the power bar and the crane host. Festoon cables can also help in electrifying jib cranes as well as monorails.

It can also act as a protection guide for gas hoses and different types of circular cables. This component is used mainly in material handling applications and different types of cranes like jib cranes, port cranes, overhead cranes, etc. They can also be used to control explosion-proof cranes and deliver energy supply to them.

The reason why festoon cables are commonly used in the apparatus of electrification is their ability to withstand extreme weather conditions like temperature and cold and their multipurpose ability to be used in indoor and outdoor environments.

It is easy to determine the difference between a festoon cable system from the other components present in the electrification system. You can monitor the speed, measure the weight, and analyze the motion of the cable system for differentiation.

A simple festoon cable system consists of a control unit that can be moved automatically as well as manually, an immobile clamp end, and reels and trolleys that secure the wires and provide support while operating a machine. It is a festoon cable job to ensure the moving equipment receives proper power supply and compressed air while it is in motion.

You can choose a heavy-duty festoon cable or a light-duty one according to your needs. The material being transported and its weight mainly determines which category of festoon cables should be used.

Read more about:

- Ultrasonic Steam Trap Testing – An Overview

- Brief Note on Sonotec Acoustic Camera

- Partial Discharge (PD) Detection and Management: A Comprehensive Guide

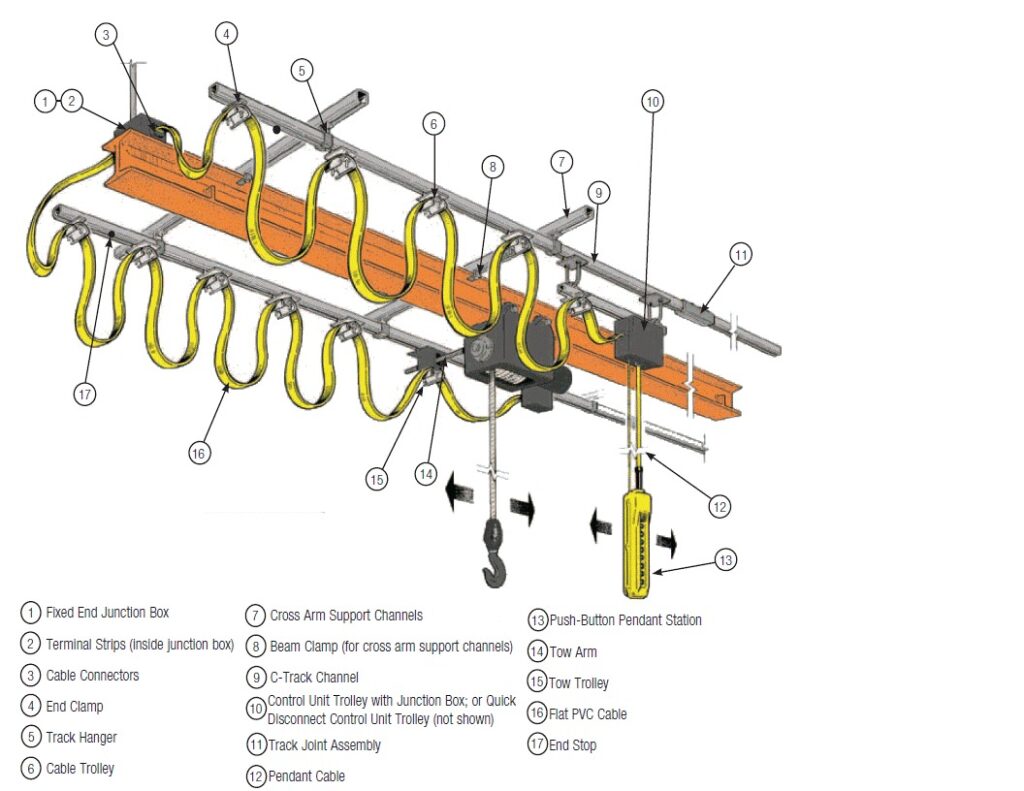

Parts of Festoon Cable System

This maintains the regulation of PVC’s movement and is located on the fixed arm.

2. Inside Junction Box

This control box is situated on the control trolley unit, which consists of terminal strips to control the movements of the trolleys.

3. Cable Connectors

Cable connectors are made of corrosion-less and flame-resistant materials and can be used for single or multiple wires. The body structure is aluminum, and the bush of the connector is rubber.

4. End Clamp

An end clamp is an immobile component in the festoon system and is installed on the fixed end of the C-Track.

5. Track Hanger

The track hanger is structured to be placed on angle iron brackets and is used to hang heavy-duty C-Track from the cross arm channels.

6. Cable Trolley

The purpose of a cable trolley is to carry electrical wiring to the end of the track. It is required in between every tow trolley and the end clamp for every single flat cable loop.

7. Cross Arm Support Channels

At least two girder arms’ support is required for a cross arm support channel to hold. It is positioned perpendicular to the I-beam.

8. Beam Clamps

These clamps make sure the cross-arm supports are properly positioned in a perpendicular state to the I-beam.

9. C-Track Channels

These are C-shaped channels through which the C track passes.

10. Quick Disconnect

A quick disconnector can be used to bridge the control box to the push button pendant.

11. Track Joint Assembly

All of the attachments are properly aligned and secured to the track with the track joint assembly.

12. Pendant Cable

Pendant cables are designed to withstand heavy weights and are used to deliver signals from the push button to the crane systems.

13. Push Button Pendant Station

This station is a hub for activities like stop and starts, alarms, emergency stops, and up and down operations.

14. Tow Arm

Tow arms are situated on the crane to move the tow box, and the bars are coated with stainless steel paint.

15. Tow trolley

A tow trolley is supposed to be the first cable carrier. The crane power supply is directly connected to the tow trolley using the tow arm.

16. Flat PVC cable

These are the black cables that provide support for all the lines. To remove the outer jacket, ripcords are also included in this.

17. End Stop

These are used to keep the end clamps tightly in place. It can also be used to keep the control trolley from rolling out of the C-Track.

You may also like to read:

- Vibration Structural Analysis: Unveiling The Dynamics Of Stable Designs

- Understanding Busbar Systems In Cranes: Powering Efficiency And Safety

- Oil Analysis In The Marine Industry By Ocean

Types of Festoon Systems

1. Heavy Duty Festoon Cable System: As the name implies, these types of festoon systems are used for heavy-duty applications. The assembling of these systems is simple, and they come in single and also double trolley variants.

2. C Rail Cable: These Festoon cables are suitable for both indoor and outdoor purposes. It comes in different kinds of coatings, like stainless steel or zinc. C Rail systems are majorly used in transportation systems, conservation techniques, and crane production. Specially manufactured variants are also available for explosion-proof locations.

3. Round Cable Flat Festoons: These cable systems are considered to be the most versatile among the festoon apparatuses. This is very flexible because of its robust design, consisting of a spherical pendant cable. The applications of this type are vast as they can be used in almost all kinds of electrification systems without fail.

4. Track Mounted Cable: These kinds of festoon cables are specifically designed for transmitting hoses or any kind of wires to deliver power to the circuits. The major features of this cable system are that it is low-maintenance and extremely easy to install. The materials used for this can be steel, galvanized steel, or even PVC. It can thrive in any extreme environment, like corrosive or dusty conditions.

5. Square Rail Festoon Systems: If you need a festoon system in an environment considered sloppy and dusty by nature, then the best choice is the square rail festoon cables. The major perk of this kind is that it lets you configure its working. If you want it to function on a straight track or a circular track, you can set up the configurations for the corresponding.

Merits of Festoon Cable Systems

The first perk is organization. Even though there are numerous wires and cables, a festoon cable can help hold these in order and not in a heaped manner. They are easy to maintain, and their functioning can be understood in layman’s terms.

Since they are manufactured in a hard manner to provide strength, they can survive in extreme conditions. It is cost-effective, and if needed, it can also be customized according to your requirements.